Complete UV Printing Guide: 13 Proven Applications for Factory Production

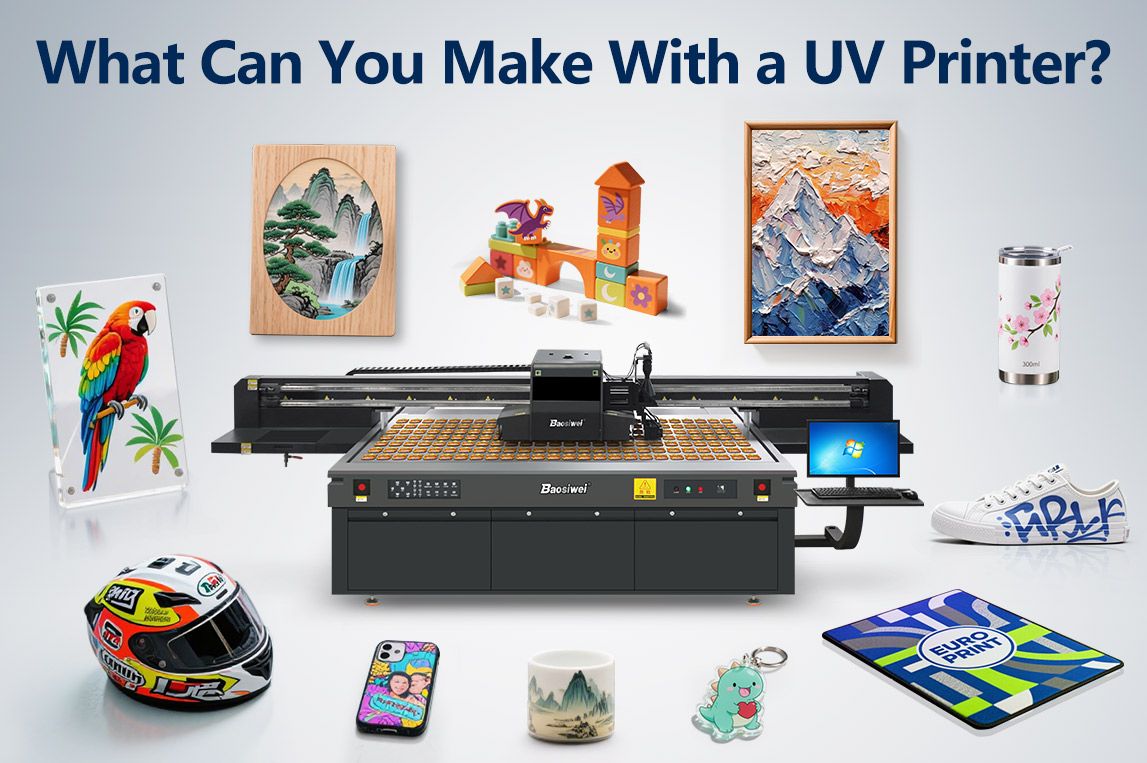

What Can You Make With a UV Printer?

Are you considering investing in an industrial UV printer? Curious about what projects it can accomplish? Perhaps you’ve already explored UV printing and want to expand your production capabilities. That’s fantastic!

Because in today’s article, we will provide you with a series of featured projects to help you fully analyze all the possibilities. Ready to explore them? Let’s get started!

Table of Contents

- Acrylic Prints

- Glass Prints

- Wood Prints

- Texture Prints

- Floor mat Prints

- Toy Prints

- Helmet Prints

- Finished shoe Prints

- Custom Refrigerator Magnets

- Custom Phone Cases

- Custom Wall Art

- Custom Stationery

- Custom Crafts

- Custom Packaging Boxes

- Print More with JW-2513UV

- The Best UV Flatbed Printer You Can Buy

Acrylic Prints

[Image Description] JW-2513UV Flatbed Printer Acrylic Printing Effect Display

Acrylic material has good light transmittance and impact resistance and can be used to make various display boards, advertising boards, and signs. Printing with a UV flatbed printer allows for high-definition, high-color-accuracy patterns and text.

It is important to note that the surface of acrylic materials may require pretreatment (such as coating treatment), and you should select high-quality inks to enhance adhesion and UV resistance of the printed design.

Leave the rest of the work to the UV flatbed printer!

(Detailed acrylic printing guide can be found in our previous blog.)

Glass Prints

[Image Description] JW-2513UV flatbed printer glass printing effect display

Glass printing can be widely applied in customized scenarios such as partitions, window decorations, and crafts. UV printing technology enables vivid color reproduction, delicate and beautiful images, and finished products with practical features such as scratch resistance, wear resistance, waterproofing, and weather resistance, meeting diverse indoor and outdoor decoration needs.

(Detailed glass printing guide can be found in our previous blog.)

Wood Prints

[Image Description] JW-2513UV flatbed printer wood fan printing effect display

Furniture manufacturers, wooden toy factories, or wood art producers often face the long lead time of screen printing. With the JW-2513UV, there is no need for plate-making — white, color, and varnish can be output simultaneously, instantly dried after printing — saving factories a large amount of time and labor costs, while adding more added value to your products through creative designs.

(For more wood printing guides, click on our previous blog posts.)

Texture Prints

[Image Description] JW-2513UV Flatbed Printer Petal 3D Texture Printing—so realistic it feels like a master’s touch!

The unique charm of UV printing: texture.

Unlike the purely visual appeal of regular printing, UV printing can freely stack ink layers to create truly raised, three-dimensional design elements. For example, in a landscape illustration, texture printing makes each petal slightly raised, creating a realistic tactile feel.

This tangible raised texture can significantly enhance product quality, making your finished pieces stand out from the competition.

For factories, this means expanding profit margins and improving market competitiveness without increasing labor or production space.

Floor Mat Prints

[Image Description] JW-2513UV flatbed printer printing leather floor mat effect display

Have you spotted the hottest floor mat business opportunity in 2025?

Floor mat factories first heat and cut the entire roll of mat material into sheets, then print the required patterns using a UV flatbed printer, and finally pack and ship. Common materials include loop pile mats, technology velvet mats, leather mats, PVC foam mats, etc. The printed patterns are vivid in color, can be printed starting from just one piece, and have excellent color fastness. This fully meets the low minimum order requirements of today’s cross-border e-commerce and small customized orders.

Toy Prints

[Image Description] JW-2513UV Flatbed Printer Toy Doll Printing Effect Display

In toy manufacturing, more and more factories are using UV flatbed printing to replace stickers or spray painting. In the toy industry, it can be applied to creative Rubik’s cubes, vacuum-formed toy cars, building blocks, cartoon figurines, and more—across a variety of materials and shapes. It supports high-drop printing and visual positioning scanning, enabling precise registration even on uneven surfaces or multi-faceted structures.

White ink, color, and varnish can be output simultaneously in one print, producing bright, detailed patterns with surfaces that are wear-resistant and waterproof.

Helmet Prints

[Image Description] JW-2513UV Flatbed Printer Vacuum-formed Helmets Effect Display

Helmet manufacturers can use UV flatbed printers to print on PVC, PC, or ABS sheets, paired with Baosiwei’s specialized vacuum-forming inks to achieve more stable finished effects. These inks ensure that during high-temperature vacuum forming—even when shaping with height differences of more than ten centimeters—the patterns remain complete and crack-free. This is suitable for ABS panels, decorative parts, toy shells, and more. For more process details, feel free to contact us.

Finished Shoe Prints

[Image Description] JW-2513UV flatbed printer printing finished shoes effect display

Sneakers, sports shoes, and canvas shoes—graffiti customization is one of the most popular UV printing applications.

Our UV flatbed printer can directly print patterns on finished shoe uppers made of leather, mesh fabric, TPU, and more—without transfer or mold opening. DIY graffiti your own personalized shoes.

(Finished shoe printing solution can be found in our previous blog.)

Custom Refrigerator Magnets

[Image Description] JW-2513UV flatbed printer printing refrigerator magnets effect display

Even small fridge magnets can play big creative roles. With UV printing, they can be turned into event souvenirs, brand promotional gifts, or unique and fun fridge decorations. Whether it’s holiday scenery, cute pet photos, motivational quotes, or mini calendars—all can be easily presented. Unlike traditional magnets, UV printing can directly output onto acrylic, wood, flexible magnetic sheets, etc., and can support embossed textures or high-saturation color effects. The prints are durable and fade-resistant, making each magnet more refined and collectible.

(Refrigerator magnet printing solution can be found in our previous blog.)

Custom Phone Cases

[Image Description] JW-2513UV flatbed printer printing phone case effect display

The JW-2513UV can produce up to 10,000 phone cases per month, compatible with a variety of materials including PC, silicone, leather, hard plastic, soft plastic, and IMD. Ink cost is less than 0.1 RMB per case, while product profit margins can increase by around five times. High efficiency, low cost, and multi-material compatibility make it the top choice for many factories upgrading their production lines.

For low-cost startup solutions, you can also choose the A3 UV flatbed printer.

Custom Wall Art

[Image Description] JW-2513UV flatbed printer wall art printing effect

In addition to outdoor advertising signs, UV printing can also be used for home décor and custom art pieces—on acrylic, wood, metal, or even glass—to create eye-catching wall decorations:

- UV-printed acrylic photos mounted floating from the wall for a levitating effect

- Wood prints combined with other materials to add handcrafted textures

Custom Stationery

[Image Description] JW-2513UV Flatbed Printer Printing Raster Effect Display

For businesses, schools, or tourist attractions, customized stationery and cultural products are a mainstay of UV printing.

Directly print on products such as power banks, phone stands, notebooks, commemorative badges, and more—embedding the brand into people’s daily lives.

The advent of UV printers has simplified special-surface printing, making it easy to customize various cultural and creative goods. Depending on your needs, you can choose a large UV flatbed printer or a small UV flatbed printer.

Custom Packaging Boxes

[Image Description] JW-2513UV flatbed printer packaging boxes printing effect

UV flatbed printers are widely used in the customized packaging sector, such as personalized or limited-edition gift packaging for wine boxes or tea boxes. They can print brand logos or text and also create embossed, varnished, or gold/silver foiling effects for greater visual impact, providing flexible and efficient packaging appearance design.

Print More with JW-2513UV

[Image Description] JW-2513UV flatbed printer displaying various compatible materials

On the production line, UV printing applications go far beyond the few products you see here. The JW-2513UV can quickly switch between different materials and processes, helping you capture more diversified, small-batch, high-value orders—keeping profits from flowing to competitors.

By staying attuned to your customer base’s latest needs and adjusting production direction at any time, you can ensure the equipment is never idle and production lines remain fully utilized. Using UV printing, you can expand more business segments within your existing plant, increasing output value while enhancing market competitiveness.

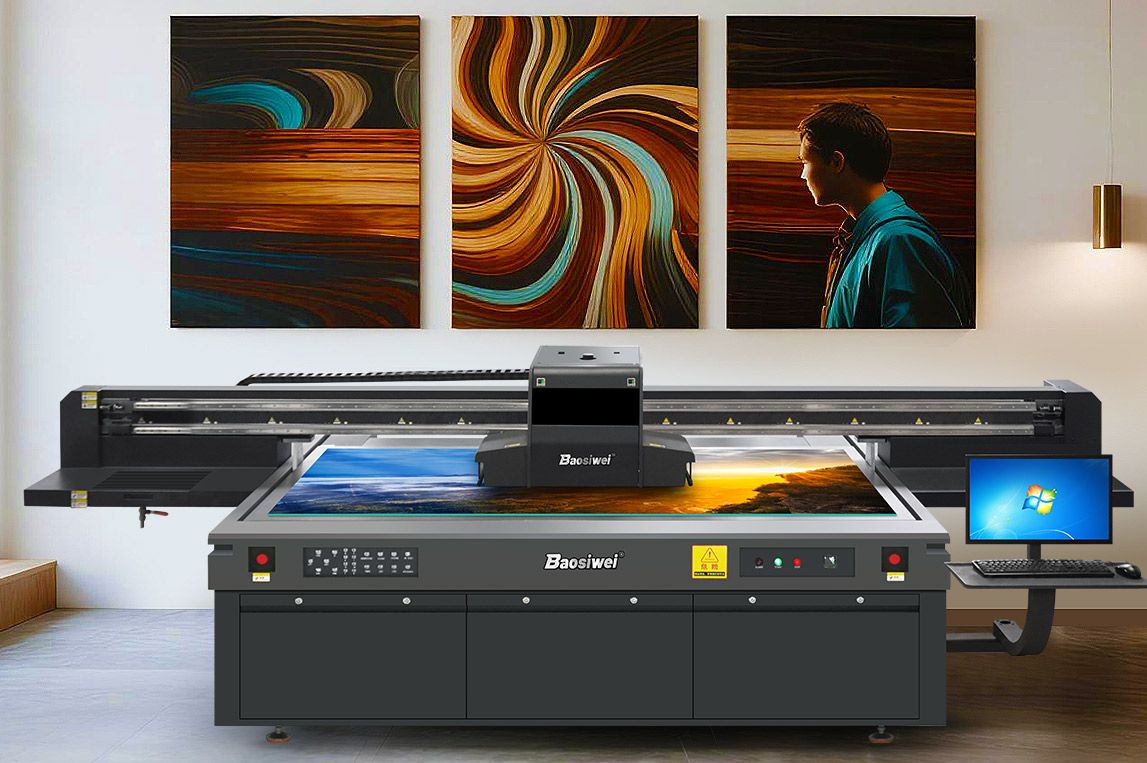

The Best UV Printer You Can Buy

If you are selecting a UV printer, consider Baosiwei’s JW-2513UV flatbed printer—known as the “do-it-all” UV printer with no material restrictions, the main industrial production model in the Baosiwei family, and arguably the most comprehensive model available.

(Click to view JW-2513 UV flatbed printer configuration details)

The JW-2513UV features an industrial heavy-duty frame and Ricoh G6 printheads, delivering 100% true-to-life color reproduction—making it the best choice for professional UV printing production. Whether for large-scale processing or small-batch precision customization, it can provide you with outstanding printing experiences.

For more Baosiwei brand models, please browse: https://www.baosiwei.com/product-categorie/uv-flatbed-printer.html