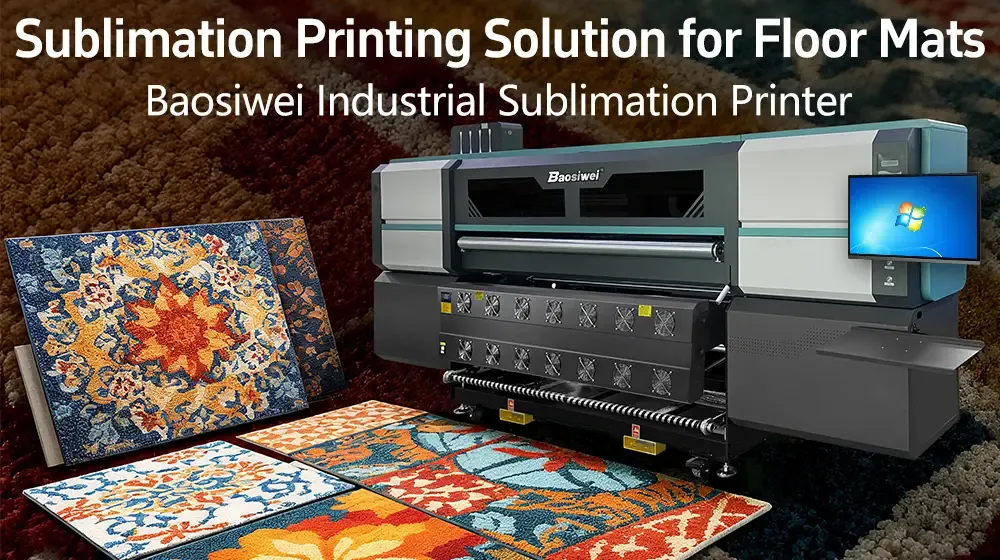

Sublimation Printing Solution for Floor Mats — Baosiwei Industrial Sublimation Printer

In the floor mat industry, manufacturers often face two core challenges:

- Limited production capacity — struggling to meet both large-scale bulk orders and personalized small-batch demands.

- UV direct printing limitations — the process often alters the physical properties of the material, reducing absorbency, softness, and breathability.

To address these issues, Baosiwei has developed an industrial-grade sublimation printer specifically for floor mats. This solution not only delivers a significant boost in production capacity but also ensures high-definition, durable designs without compromising the original material properties.

Why Choose Sublimation Printing for Floor Mats?

The printing method directly determines product quality and customer retention in the floor mat industry. Although UV direct printing is simple in process, it comes with three major drawbacks:

- Cracking and fading: Floor mats endure frequent stepping and friction; UV-printed graphics tend to wear out or fade over time.

- Environmental concerns: The UV curing process releases odor and may not comply with international safety and eco-friendly certifications for home products.

By contrast, sublimation printing solves these problems at the root:

- Ink transforms into gas under high temperature and penetrates directly into the fibers — no rigid coating forms on the surface.

- The material’s natural properties remain intact: absorbency, softness, and breathability are fully preserved.

- Uses eco-friendly water-based inks — odorless, non-toxic, and compliant with strict safety and environmental standards in Europe and North America.

- Finished products achieve high colorfastness, with vivid, long-lasting patterns that won’t fade — ideal for floor mats that demand durability.

Sublimation is more than just a printing choice — it’s the key for floor mat factories to compete on both quality and compliance in today’s market.

Massive Boost in Production Capacity

In a competitive market, delivery speed often decides whether a client continues cooperation. Baosiwei’s industrial sublimation printer is engineered to meet the demands of high-volume floor mat factories:

- 15 industrial printheads — multi-head system ensures ultra-fast printing, reaching up to 500 m²/hour.

- 2.2-meter wide format — covers standard mat sizes in one pass, reducing seams and interruptions.

- Roll-to-roll feeding system — supports long runs and stable 24/7 continuous production.

- Smart monitoring mode — allows a single operator to manage multiple machines, cutting labor costs and increasing efficiency.

Case study: A factory equipped with two Baosiwei sublimation printers achieved a daily output of over tens of thousands of square meters, enabling them to handle large export orders while keeping delivery consistent.

Conclusion: For factories facing diverse order types and production pressure, the Baosiwei sublimation solution delivers exponential gains in capacity.

Standardized Production Workflow

Sublimation is not only efficient but also highly controllable and stable — helping factories establish standardized, repeatable processes:

Digital design — Patterns are prepared on computer software, then imported into RIP for color and resolution control.

Sublimation transfer paper printing — High-speed output on transfer paper reduces risks of direct misprints on materials.

Heat transfer process — Using a heat press or calender, the ink sublimates and penetrates the fibers.

Quality check and packaging — Results are sharp, vibrant, durable, and eco-friendly, meeting home décor and export standards.

Value to factories:

- Stable quality — eliminates color shifts and defects caused by manual or inconsistent methods.

- Scalable and replicable — standardized processes make it easy to train operators and expand production lines.

- Reduced waste — fewer misprints and less material loss.

- Reliable lead times — clear workflows allow precise delivery commitments.

Conclusion: Standardization means factories can not only produce faster but also more reliably, meeting international clients’ dual demands for quality and on-time delivery.

Which Factories Benefit Most from This Solution?

The Baosiwei sublimation printing solution is ideal if your factory meets the following conditions:

- Specializes in diatomaceous mats, synthetic fiber mats, faux cashmere mats, or polyester-based mats with ≥65% polyester content.

- Handles both bulk orders and personalized small-batch production.

- Requires vivid colors, high colorfastness, and preservation of material properties.

- Serves clients demanding odor-free, eco-friendly, and safe home products.

Baosiwei Sublimation Printer for Floor Mats empowers manufacturers to balance capacity, quality, and environmental compliance — giving your factory a competitive edge in both domestic and global markets.

If you’re producing mats or exploring opportunities in the mat market, and want a more detailed solution or personalized machine recommendation, don’t wait — contact us today by filling out the form: https://www.baosiwei.com/contact.html. The Baosiwei team will provide expert guidance and help you choose the best equipment to maximize efficiency and results.