What is a Digital Printing Printhead? Function and Working Principle

What is a Digital Printing Printhead? Function and Working Principle

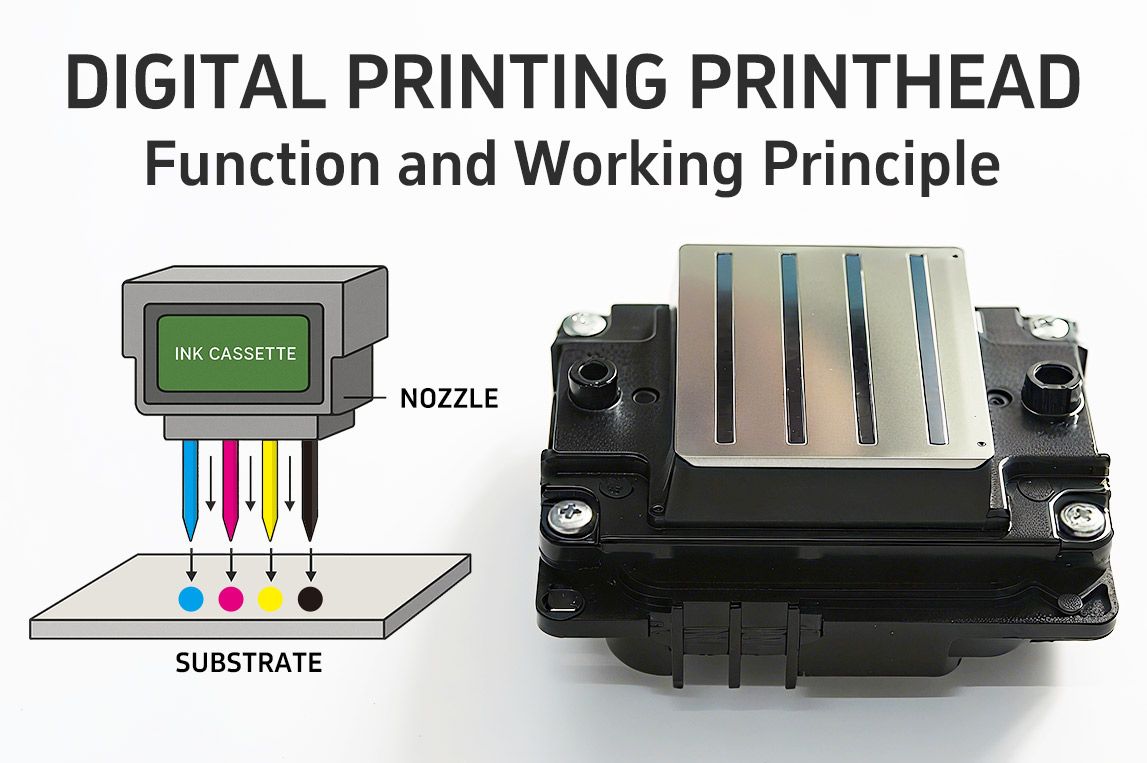

In any digital inkjet printer, the printhead is the core component that precisely sprays ink onto the media to form images and text.

Whether it’s a desktop inkjet printer, a large-format printer, or an industrial UV flatbed printer, the printhead’s performance directly impacts sharpness, color accuracy, and production efficiency.

With nearly 30 years in the digital printing equipment industry, Baosiwei has hands-on experience in selecting and fine-tuning printheads for various applications.

For example, in our UV Hybrid printers, industrial UV flatbed printers, coated paper printers, and textile printing machines, we integrate Ricoh G6 printheads and Epson i3200 printheads to match different industries and processes—delivering high-definition prints without slowing down production.

Main Types of Digital Printing Printheads & Applications

1. Piezoelectric Printheads for Industrial Printing

Principle: Piezoelectric ceramics deform when voltage is applied, pushing ink droplets out with extreme precision. Drop size can be adjusted by voltage, ensuring consistent quality.

Applications: Popular in industrial inkjet printing due to high precision, long lifespan, and compatibility with multiple ink types, including UV, solvent, and water-based inks.

Example: Baosiwei’s JW-2513 UV flatbed printer and JW-1908 UV hybrid printer use Ricoh G6 printheads and Epson i3200 printheads for high-precision printing with white, color, and varnish in a single pass—ideal for UV printing on glass, acrylic, wood, and metal.

2. Thermal Inkjet Printheads

Principle: Heats ink inside the nozzle to create a vapor bubble, forcing the ink out.

Applications: Common in office inkjet printers and photo printers by brands like Canon and HP. Ideal for low-cost, short-run printing.

3. Continuous Inkjet (CIJ) Printheads for High-Speed Coding

Principle: Ink is sprayed continuously at high speed, and an electric field directs droplets to form text or images.

Applications: Used in high-speed production lines to print expiry dates, batch codes, or QR codes on food packaging, pharmaceuticals, and electronics.

4. Drop-on-Demand (DOD) Printheads for Precision Graphics

Principle: Ink is ejected only when needed, driven by pressure or heat.

Applications: Perfect for multi-color and complex patterns, used in advertising, signage, textiles, and building materials.

Key Components of a Printhead

- Nozzles – Affect resolution and image clarity

- Ink channels & chambers – Maintain smooth ink flow

- Drive unit – Piezoelectric elements or heating components

- Control circuits – Synchronize droplet ejection

- Cooling system – Prevent overheating during long runs

- Ink supply system – Stable ink delivery for consistent printing

At Baosiwei, every printhead setup undergoes strict calibration to ensure optimal performance in UV flatbed printing and industrial inkjet printing environments.

Performance Factors that Affect Output Quality

- Resolution (DPI) – Higher DPI means sharper details

- Print speed – Influenced by nozzle count and ink delivery speed

- Drop size – Smaller drops produce smoother gradients

- Durability – Industrial heads can last years with proper care

- Ink compatibility – Choosing the right ink prevents clogging and extends lifespan

Maintenance & Replacement Tips

Using poor-quality ink or neglecting maintenance can cause nozzle blockages.

Baosiwei printers feature automatic printhead cleaning systems and user-friendly maintenance guides, allowing piezo printheads to last 3–5 years even under heavy industrial workloads.

Final Thoughts

The printhead is the heart of any digital printing machine. It determines not only print quality but also production speed and cost efficiency.

With Baosiwei’s combination of technical know-how and decades of industry experience, we help businesses choose the best printhead solution for their UV printing, textile printing, and industrial inkjet printing needs—balancing image quality with production efficiency.