UV Printer Key Performance Parameters & Core Components — Supplement | Baosiwei

UV Printer Key Performance Parameters & Core Components — Supplement | Baosiwei

Note: This article supplements our previous guide, “2025 UV Printer Selection & Pricing Guide”. Its primary purpose is to provide more detailed instructions on how to understand specifications, conduct sample testing, and perform acceptance checks. This will help customers make more accurate decisions and handle issues during machine procurement and operation. Please read the main guide first: https://www.baosiwei.com/zh/news/2025-uv-printer-selection-pricing-guide.html (If already read, proceed directly to this article).

Key Performance Parameters Explained

When selecting equipment, don’t only look at price — core parameters determine long-term capacity and product quality. Below each item explains why it matters and how to test/verify so you can judge whether equipment matches your business using data and samples.

Printing Speed (Throughput)

Why it matters

Printing speed directly affects output per unit time, labor costs, and delivery capability. Insufficient speed will lead to production bottlenecks, affecting order intake and customer satisfaction.

How to read / interpret specs

Common units: m²/h (square meters per hour) or ft²/h (square feet per hour). Speed is affected by resolution (DPI) and number of passes (DTF): higher resolution and more passes decrease speed.

Typical ranges (reference)

- A3 UV flatbed printer: 0.28 – 3 m²/h;

- 6090 medium flatbed printer: 10–12 m²/h;

- UV DTF crystal-label machines: ≈3–10 m²/h;

- 2513 industrial flatbed printer: 18–30 m²/h (depending on configuration).

How to test / verify

- Ask the vendor for “production-mode measured speed” (not theoretical speed at the lowest resolution);

- Run a full production demo using your typical SKUs (including loading/unloading, positioning, and post-processing), record whole-process throughput;

- Calculate “end-to-end capacity”: consider not only printhead travel time but also loading, waiting, curing/drying, and manual placement cycles.

Acceptance example: For a common part (e.g., a single phone case 0.02 m²), vendor throughput should approximate your expected hourly output (with stated margin of error).

Print Quality (DPI, drop size, ink configuration)

Why it matters

Determines final product visual appearance and brand color reproduction ability; directly affects whether you can accept high-demand orders (e.g., brand packaging, electronics housings).

Key parameters explained

- DPI (Dots Per Inch): higher DPI expresses finer detail, but reduces speed.

- Ink drop volume (pl): smaller drops produce smoother gradients and finer detail; larger drops are suitable for ink build-up, relief, and highlight effects.

- Ink channels: common configurations include CMYK, CMYK+W (white), CMYK+W+V (varnish/clear), which affect printing on dark substrates and local gloss effects.

How to test / verify

- Request manufacturer samples and compare physical outputs: same artwork printed on different machines (image detail, gradients, small text, solid blocks, local varnish effects);

- We usually recommend customers bring their materials to the factory for on-site sample printing;

- Test items include image rendering, text and fine lines, gradient strips, solid areas, white ink coverage, and varnish feel.

Tools: Use a spectrophotometer to measure ΔE (target: ΔE ≤ 2–3 on identical color patches is preferable).

Acceptance criteria: Sharp edges, smooth gradients, white ink without noticeable banding and with required opacity, varnish without flow marks or unevenness.

Printing Size & Media Thickness (width × length × height)

Why it matters

Affects whether your common products can be printed in one pass, whether splicing or additional fixtures are needed, and the subsequent jig/fixture costs.

Notes

- Manufacturer “machine dimensions ≠ usable printing area”;

- Check usable area and maximum printing height (height clearance);

- For cylinders or irregular objects, confirm whether corresponding fixtures or rotary devices are available.

How to test / verify

- Ask the vendor to specify the usable printing area and demonstrate printing of your specified-size physical items during installation;

- Measure height clearance and fixture compatibility on-site; test thick items and large height differences (samples of different thicknesses).

Ink Layer Height / High-drop Printing (High-drop)

Why it matters

Used on highly textured or irregular surfaces (e.g., golf balls, textured surfaces, pitted surfaces) to ensure ink coverage and pattern integrity.

How to test / verify

- Ask the vendor for the theoretical maximum printing height (mm) and whether high-drop mode is supported;

- Print on representative textured samples (e.g., perforated balls, carved wood boards) and check ink adhesion, continuity (no breaks), and color saturation;

- Check positioning and repeatability, especially for multi-color overprint alignment.

Automation & Software (Workflow)

Why it matters

Software and automation determine production stability during fluctuations, labor costs, and daily operational efficiency. Good software reduces human error, increases throughput, and improves color consistency.

Key functions

- RIP and color management (ICC support);

- Job queuing, batch processing, variable data printing (VDP);

- Auto loading/unloading, vision positioning, remote monitoring, logs, and reports;

- API / ERP / MES integration capability (for industrial production lines).

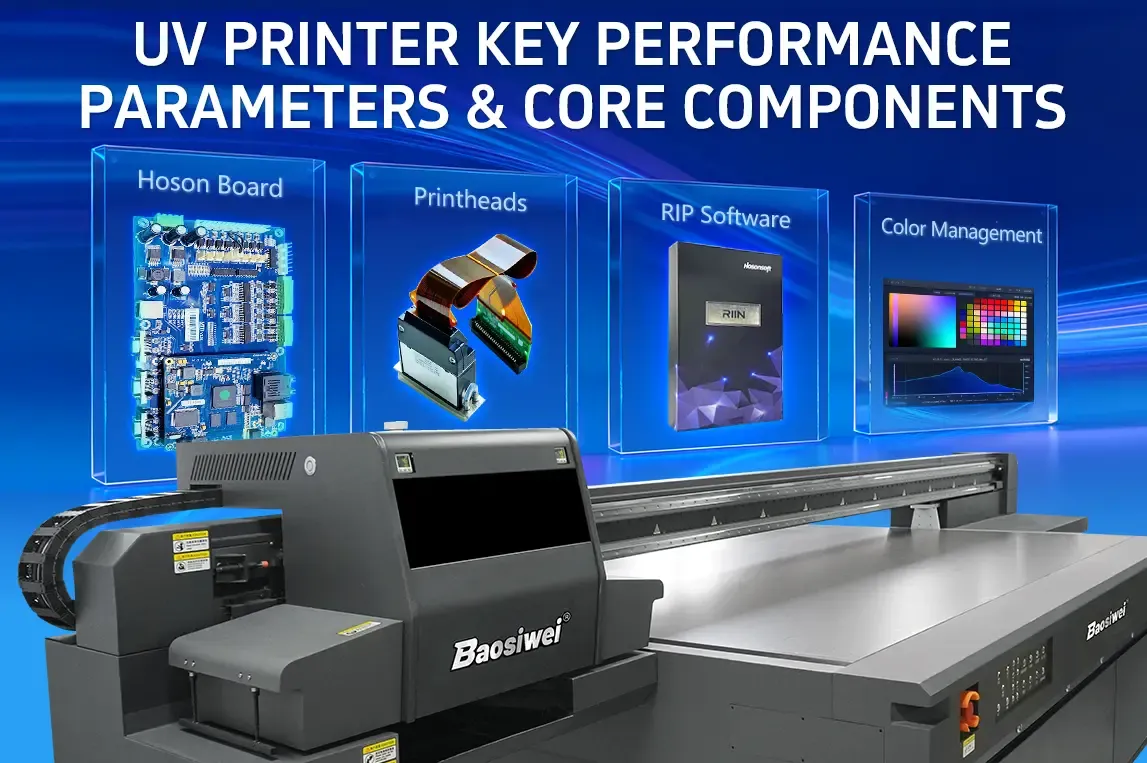

Boards / Printheads / Software / Color Management (Core Component Primer)

This section explains, from a parts perspective, why these items are critical to long-term stability and capacity and provides a checklist of technical questions for machine acceptance / comparison.

Controller Board — the source of stability

Role

Controls the machine motors, printhead drivers, IO interfaces, and signal scheduling; it’s the “brain” of motion precision and printing stability.

Why it matters

The board’s computing power, anti-interference design, and firmware affect print consistency, speed, and positioning accuracy. Poor boards cause disconnects, misalignment, and artifacts.

Points of focus / verification methods

- Processor and real-time control capability: ask whether it’s an RTOS architecture or industrial-grade MCU/FPGA;

- Anti-interference and interface stability: check EMI shielding, grounding, and power filtering design;

- Scalability: whether it supports more printheads, vision systems, or automation modules;

- Firmware upgrades and log recording: whether it can be upgraded remotely and export error logs for troubleshooting.

Acceptance test: Long continuous run (recommended 8–24 hours) to check for disconnects, dropped frames, or repeat positioning errors.

Printhead — the core of precision and speed

Why it matters

Printheads directly determine print accuracy, color consistency, and speed; their performance sets the quality ceiling for orders you can accept.

Main vendors & differences

Ricoh, Kyocera, Seiko, Xaar, Konica Minolta, etc., each with different jet frequency, minimum drop volume, and durability.

Key parameters

- Minimum drop volume (pl);

- Jet frequency (kHz);

- Printhead lifetime (operating hours or ink throughput);

- Nozzle density and resolution support.

Maintenance & assurance

- Spare parts strategy: recommend keeping 1–2 key spare printheads, especially for mid/high-end production lines;

- Cleaning mechanisms: automatic cleaning / wet storage can significantly extend printhead life.

How to verify: Perform nozzle checks, long-run sample printing, simulated clogging & recovery tests to assess maintenance convenience and mean time to repair (MTTR).

Software System — intelligence & process control

Why it matters

Software determines efficiency and daily maintenance difficulty: from file-to-product workflow automation, color reproduction, to one-click jobs — all significantly affect labor cost and error rates.

Core feature checklist

- RIP features and processing speed (large file handling);

- ICC / color management integration and easy profile management;

- VDP and batch job management;

- Remote diagnostics, logs, and reports (for production efficiency analysis).

How to test

Ask the vendor to demonstrate complex job layout, color profile import, variable data printing, and remote monitoring on-site; run one complete job using your real files to verify compatibility.

Baosiwei highlight: Baosiwei provides industry-specific software packages (phone case, bottle, metal/plastic templates) and convenient “One-Click Repair” remote support to significantly shorten customer ramp-up time.

Color Management — ensuring true color reproduction

Why it matters

Color consistency is a hard requirement for brand orders; without reliable color management, batch production risks serious color shifts.

Key concepts

- ICC profile: a color mapping table built for a single substrate/ink combination;

- Spectrophotometer / color difference (ΔE): numeric measure of screen-to-print discrepancy. Industry target: ΔE00 ≤ 2 (excellent), ≤ 3 (acceptable);

- Spot color (PANTONE) management: mapping brand spot colors to CMYK/device and ensuring stable output.

Practical suggestions

- Build a substrate library: document each common substrate (measure, ICC file, print settings);

- Perform first-run color calibration: scan control strips with a spectrophotometer and generate ICC profiles to save in RIP;

- Set up daily QC process: print control bars, measure and log ΔE, trigger alerts and corrective actions when out-of-tolerance;

- Partner labs: work with color instrument vendors (like X-Rite) or third-party labs for periodic calibration and validation.

Baosiwei highlight: Baosiwei co-operates with X-Rite to build a color lab and has mature color management processes to provide consistent color solutions across substrates.

Why choose Baosiwei?

Why do more customers finally choose Baosiwei among many UV printer brands? The answer is that we offer not just machines but a complete industry-grade solution to help customers achieve efficient production + cost optimization + market competitiveness.

1. Full product range Whether you are a startup or require 24/7 high-speed capacity in an industrial plant, Baosiwei offers matching product lines: entry-level, mid-range commercial, and industrial flagship.

Benefit: Customers won’t need to switch brands as business grows — Baosiwei supports the full lifecycle from entry to industrial.

2. Eco-certified inks, compliant with global standards Baosiwei inks are certified by SGS, VOC, OEKO-TEX, Adidas A-01, ensuring eco-safety while maintaining high adhesion, wear resistance, and water resistance.

Benefit: Customers can expand global markets without worrying about eco compliance or testing issues.

3. Professional color management system Baosiwei co-operates with X-Rite to build a color lab and works deeply with PrintFactory, ColourGate, Wasatch and other color management software:

- Ensure faithful color reproduction and batch stability;

- Achieve “what you see is what you get,” reducing rework and waste;

- Help customers quickly build enterprise-grade color standardization processes.

Benefit: Color is competitiveness — especially in advertising, home decor, and textiles, precise and consistent color determines customer satisfaction and brand reputation.

4. Global service network Domestic coverage: 20+ service centers and subsidiaries forming a fast-response network; Overseas: established subsidiaries and sales channels in Vietnam, Indonesia and other regions, serving thousands of enterprises worldwide; One-Click Repair App: remote diagnosis, video guidance and field service dispatch to solve problems quickly.

Benefit: Customers receive standardized, rapid technical support and after-sales service anywhere.

5. Customer value philosophy Baosiwei insists: “Helping customers increase value is the only reason we exist.”

This is implemented by:

- Providing industry training and market analysis to customers;

- Continuously optimizing equipment and processes to reduce total production cost;

- Helping customers quickly enter new markets and enhance competitive barriers.

Benefit: Choosing Baosiwei is not only buying machines, but gaining a long-term win-win partner.

Conclusion & CTA

A UV printer’s long-term value lies not just in its upfront cost, but in the combination of throughput, print quality, automation, and core component reliability.

If you would like us to run a comparison sample print using your real SKUs or produce an “end-to-end capacity & quality assessment report”, please contact us via the form and mark “Machine Acceptance / Sample Request” — we will send the sample plan, required sample list and quotation:https://www.baosiwei.com/contact.html

Baosiwei — leveraging 30 years of digital-printing expertise to help customers build sustainable production capacity and business growth.