How to Master Dye Sublimation Printing | Baosiwei Digital Printing Guide

How to Master Dye Sublimation Printing: A Practical Guide for Professionals

In today’s textile and soft signage industries, digital dye sublimation printing has become an essential tool for manufacturers needing precision, speed, and adaptability. Whether you’re supplying custom fashion lines, promotional banners, or home decor textiles, mastering this print method can significantly boost your production capabilities.

This article walks through the fundamentals of dye sublimation printing — without the hype. It’s designed for decision-makers in production environments who want to make well-informed choices.

What Is Dye Sublimation Printing?

Dye sublimation is a heat-based printing technique that uses specially formulated inks to transfer images onto polyester fabrics or coated materials. Unlike surface printing methods, sublimation transforms solid dye directly into gas, which embeds into the fiber or coating. The result is a sharp, durable image with excellent wash and wear resistance.

Why It’s Becoming the Preferred Choice

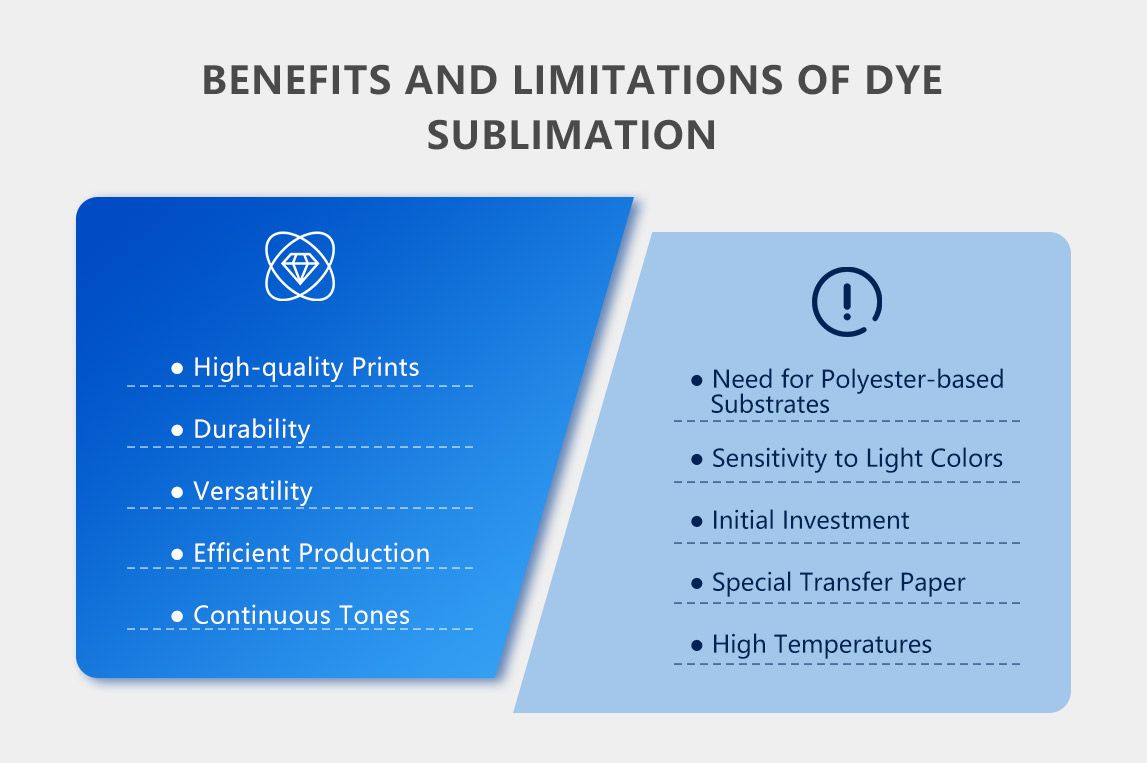

For factory buyers and production teams, here’s why dye sublimation is worth attention:

- Color Clarity: Wide color gamut and smooth gradients make it ideal for high-end retail and interior textile applications.

- Production Stability: No cracking or fading — the image becomes part of the material.

- Short Runs and Customization: Perfect for personalized products and smaller batch orders, without plate setup.

- Efficient Workflow: When matched with the right machinery, the process allows for streamlined roll-to-roll production.

Equipment Overview

1. Sublimation Printer

(Click on the image to learn more)

Key points to consider:

- Width: 1.9 meters is standard for apparel, curtains, and bedsheets.

- Printheads: Industrial Epson i3200 heads are common for their balance of speed and sharp detail.

- Color: CMYK is standard, with optional light colors for finer tonal transitions.

2. Transfer Paper

Not all paper performs equally. Look for:

- Consistent coating

- Minimal shrinkage

- Fast drying and smooth ink release

3. Heat Transfer Machine (Calender)

A precise calender ensures stable production. Key factors:

- Consistent temperature between 180°C and 210°C

- Adjustable speed and pressure

- Roll-to-roll capability for fabric lengths

Production Tips

- Use matched ink and paper to maintain consistent quality.

- Test materials beforehand — not all polyester behaves the same.

- Calibrate your calender regularly to avoid ghosting or edge fade.

Where It’s Used

- Home Textiles: Curtains, cushions, tablecloths

- Sportswear: Jerseys, leggings, polyester activewear

- Soft Signage: Trade fair graphics, flags, backdrops

Sublimation excels in applications where durability, wash resistance, and color impact matter.

Is It the Right Fit?

This method works best for manufacturers focused on polyester-based materials. If you’re shifting toward shorter lead times, custom SKU production, or more sustainable workflows, sublimation is worth considering.

The process does require dedicated equipment and knowledge — but once optimized, it delivers reliability batch after batch.

Final Word

No print method is one-size-fits-all. But for producers of soft goods, dye sublimation offers a proven path to vibrant, scalable, and repeatable output. With the right setup and planning, it’s a solid choice in today’s evolving manufacturing landscape.

Whether you’re just starting with polyester printing or looking to upgrade your production workflow, Baosiwei provides the tools, expertise, and technical support to help you succeed. Our team is here to walk you through the process—from equipment selection to output optimization.

Have questions or want to see how dye sublimation fits into your operation?

Feel free to reach out. We’re ready to support your printing journey.